Lucideon’s 3DStrain testing service can offer you vital insights and understanding into performance, durability, and failure analysis of your materials and products when interacting with external forces, weights, strains and stresses.

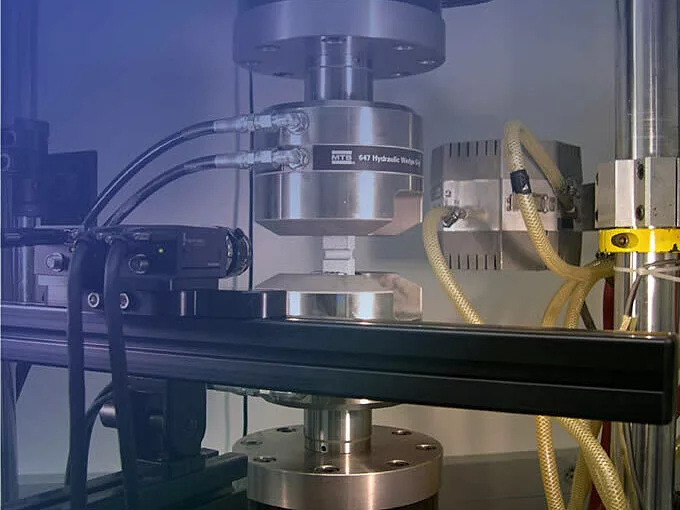

Using Digital Image Correlation (DIC) technology our experts can perform testing and analyze the detailed data to provide you with clear, simple, quantitative results.

Digital image correlation is a non-contact optical technique for measuring motion and deformation of objects by comparing digital images of the object before and after deformation. It’s used for a wide variety of applications from characterizing material properties to identifying structural damage and quality testing in manufacturing.

3DStrain can deliver non-destructive, full-field surface strain measurements on objects under load. We deliver movement tracking at the pixel-level on most materials, for a range of sizes on complex geometries.

With Lucideon you receive full analytical interpretation of the data from our experts, allowing you to make use of the vast, in-depth feedback quickly and easily.

3DStrain also produces visual results that show how strains and cracks develop and grow, up to the point of failure.

Our 3DStrain service offers you detailed digital imagery showing the displacement on your product, correlated against a no-load condition.

3DStrain testing has applications in the construction, aerospace, healthcare and nuclear sectors.

Lucideon has a comprehensive quality assurance program, which is in compliance with 10CFR50 Appendix B, ISO 17025 and Nadcap (aerospace and defense industries).

These rigorous QA requirements are applied to every job we perform as standard.