Ceramics are everywhere. Developing the next generation of products and getting them to market, quickly and cost-effectively is key. Not only does Lucideon test materials and products for raw material assessment, product development and quality control, but also, we test for product and material evaluation conformity, safety, legislative, and environmental impact purposes. This is to ensure that products are fit-for-purpose and ranges across the traditional and technical ceramics industries.

Through our UKAS ISO 17025:2017-accredited laboratories, we offer manufacturers, retailers, and importers full materials and product testing of all ceramic items to international standards.

We test at all stages of the product lifecycle from prototyping to during processing and in use.

We also offer determination of physical properties such as grading, density, porosity, strength, rheology, mechanical, electrical and thermal properties and microstructure to study product failure or defects, failure mechanisms, inclusions, grain size and bonding structures, surface analysis, degradation and contaminants.

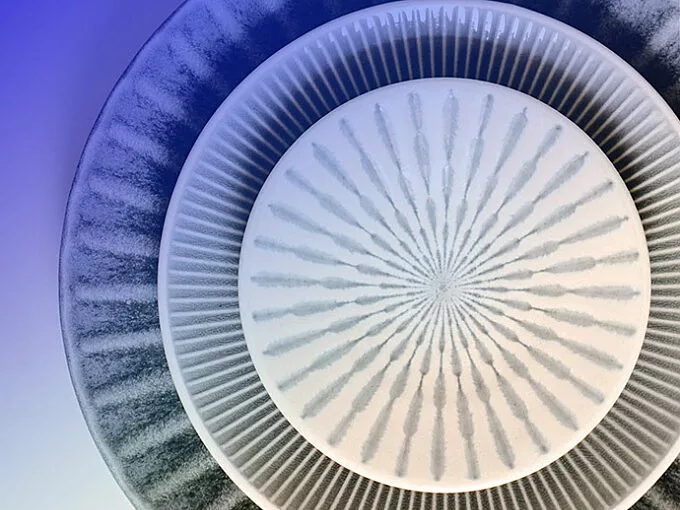

Typical work involves the analysis and testing of tiles, tableware, construction products, sanitaryware, refractories, raw materials and advanced ceramics.